1. Automotive Sealing Component Production: Jwell has engineered a specialized processing technology that enables the flexible extrusion of thermoplastic elastomers (TPEs). Using robotic guidance, sealing profiles can be applied directly onto workpieces in an automated, single-stage molding procedure. For instance, the Santoprene TPV robotic extrusion system, co-developed by Jwell, is capable of moving in three-dimensional space to deposit intricate 3D sealing profiles directly onto substrates. This approach is suitable for applications such as door seals, gutter seals, and windshield seals. It not only reduces labor requirements and minimizes material waste but also helps achieve up to 70% weight reduction in automotive components.

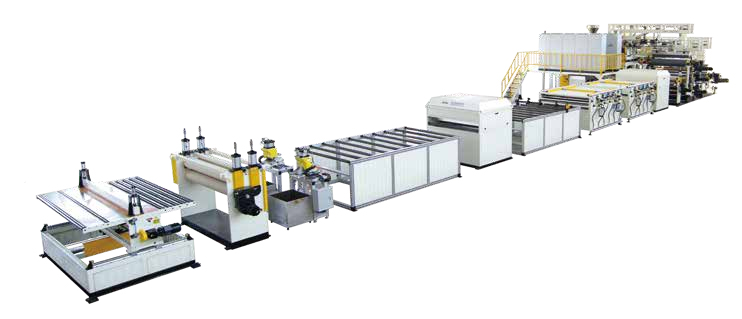

2. Automotive Interior Sheet Manufacturing: Automotive interior sheet extruders can process plastic raw materials such as polypropylene (PP), polyvinyl chloride (PVC), and thermoplastic elastomers (TPEs) into sheets with specific thickness, width, and performance requirements. These sheets are used in the manufacture of automotive interior components such as dashboards, door panels, center consoles, headliners, and carpets. Subsequent thermoforming and surface treatments of these sheets enhance the aesthetics and comfort of automotive interiors while meeting environmental, safety, and durability requirements.

3. Automotive Fuel Line Production: Plastic extruders can be used to produce automotive fuel lines. Extruded fuel lines can be 40%-60% lighter than metal parts, contributing to vehicle weight reduction and improved fuel efficiency.

4. Automotive Battery Separator Manufacturing: In the new energy vehicle sector, plastic extruders can be used to produce battery separators. The battery separator is a key component of the battery, significantly impacting its performance and safety. Battery separators produced through extrusion processes have excellent permeability and barrier properties, effectively preventing short circuits between the positive and negative electrodes while allowing lithium ions to pass through, ensuring normal battery charging and discharging.

5. Automotive Modified Material Processing: Most automotive parts cannot be directly processed from base resins and require modification, such as alloying, reinforcement modification, and filler modification.