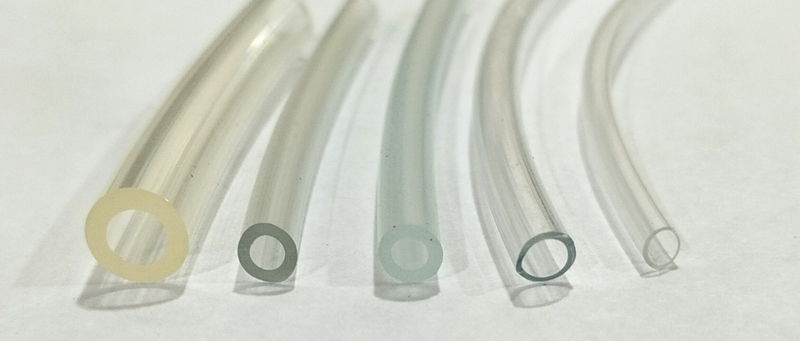

1. Medical Tubing Production: Used to manufacture various medical catheters, such as infusion tubing, urinary catheters, central venous catheters, anesthesia tubing, and endotracheal tubes. These catheters are typically made of medical-grade materials such as PP, PE, PVC, and PU. Plastic extruders can precisely control temperature, pressure, and speed to ensure dimensional accuracy, surface smoothness, and biocompatibility of the tubing, meeting the high safety and reliability requirements of the medical industry.

2. Medical Film and Sheet Manufacturing: Medical-grade plastic films and sheets can be produced, such as sheets made of polycarbonate, polyethylene, and polypropylene. These sheets have precise thickness, transparency, and sterilization compatibility, and can be used to manufacture surgical trays, infusion set components, dialyzer components, and packaging for various medical devices.

3. Medical Bag Production: By extruding specific materials, such as polyethylene or polypropylene, using plastic extruders, medical bags with puncture resistance, flexibility, and barrier properties can be manufactured, including intravenous infusion bags, blood bags, and fluid collection bags, for the storage and delivery of medical fluids.

4. Medical Consumables Manufacturing: Manufacturing plastic components for medical consumables, such as syringe pistons, needle protectors, medical connectors, and drainage device components. Plastic extruders can produce components with high precision and good physical properties, ensuring the proper use of medical consumables.

5. Biodegradable Medical Product Manufacturing: With increasing focus on environmental protection and sustainable development, the application of biodegradable materials in the medical field is gradually increasing. Plastic extruders can be used to process biodegradable materials, such as polylactic acid (PLA), to produce biodegradable medical tubing, sutures, tissue engineering scaffolds, and other products, reducing environmental impact.