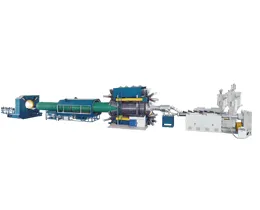

The corrugated pipe extruder is a core device specialized in producing plastic corrugated pipe (pipes with periodic corrugations on the wall). Using materials such as PE, PVC, and PP, the extruder melts and plasticizes the material through a screw, then continuously extrudes the corrugated pipe structure through a special forming die and shaping device. It precisely controls corrugation size, wall thickness, and ring stiffness, offering high production efficiency and strong stability. It is suitable for corrugated pipe applications such as municipal sewage disposal, telecommunication wiring, and agricultural irrigation.

The corrugated pipe production line has the comprehensive advantages of wide raw material compatibility (suitable for various materials such as PE, PVC, PP, etc.), continuous and stable production of corrugated pipes of different diameters/structures, high degree of automation and accurate forming accuracy (ensuring the regularity of the corrugated structure), good pressure and impact resistance of the finished pipes, low energy consumption and convenient operation.