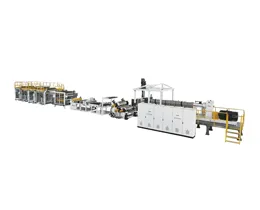

The PET sheet production line is an automated production equipment that uses a single-screw or twin-screw extruder to melt and plasticize PET raw materials, extrude them into shape through a mold, and then uses cooling, traction, cutting and other equipment to work together to produce single-layer or multi-layer composite PET sheets with a thickness of 0.15-2mm and a width of up to 1500mm.

The PET sheet production line has a wide adaptability to raw materials and can process a variety of materials such as PET, PETG, and recycled materials. It does not require a pre-crystallization and drying system and has low energy consumption. At the same time, it has efficient production capacity, excellent product quality, and can accurately control sheet thickness and flatness. It also has the advantages of high automation and flexible co-extrusion technology, which can meet the strict requirements of PET sheet in many fields such as food and electronics.