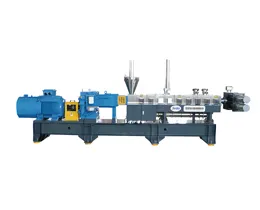

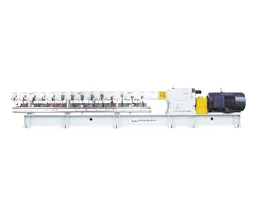

Jwell Compounding Machine, Twin-screw pelletizing equipment, is a highly efficient plastic compounding and pelletizing machine. Utilizing two intermeshing or counter-rotating screws, it continuously processes raw material conveying, melt plasticization, shear mixing, degassing and devolatilization, and extrusion pelletizing to modify, compound, and recycle plastic raw materials.

This core equipment is used in the production of modified plastics. By adding reinforcing materials such as glass fiber and carbon fiber, or functional additives such as flame retardants and antioxidants, it produces high-performance modified plastics with enhanced, flame-retardant, and weather-resistant properties. These are suitable for applications requiring high material properties, such as automotive parts and electronic housings.

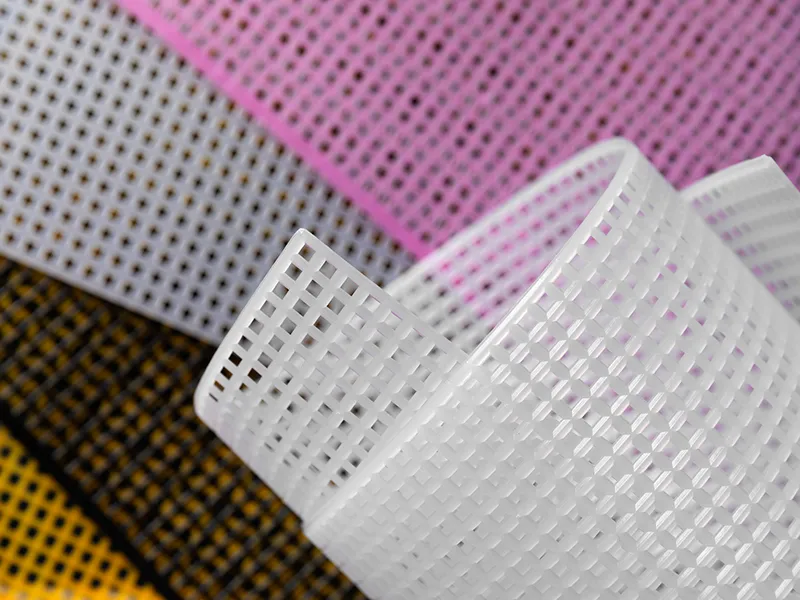

This equipment can thoroughly mix and disperse pigments and dyes with carrier resins to create high-concentration masterbatches. It can also produce functional masterbatches with antistatic, antibacterial, and toughening properties for plastic coloring and functionalization.

This equipment removes impurities and uniformly plasticizes mixed and impure waste plastics (such as PP/PE mixed waste and engineering plastic scraps) through the shearing and mixing action of a twin-screw extruder, achieving high-quality utilization of the recycled material. This is suitable for recycled plastic applications such as packaging and building materials.

This equipment can mix and granulate degradable resins such as PBAT and PLA with fillers (such as starch) to produce fully degradable plastic granules for use in eco-friendly products such as degradable films and tableware. Highly Filled Composite Material Production: This facility can process materials with high filler ratios (such as wood powder-filled PP and calcium carbonate-filled PE) to produce wood-plastic composites and filled and modified plastics, meeting the demand for low-cost, high-performance materials in the furniture and building materials sectors.

This facility can process materials with high filler ratios (such as wood powder-filled PP and calcium carbonate-filled PE) to produce wood-plastic composites and filled and modified plastics, meeting the demand for low-cost, high-performance materials in the furniture and building materials sectors.

This facility is suitable for blending and alloying engineering plastics such as PA, PC, and POM, as well as granulating specialty plastics (such as high-temperature and corrosion-resistant plastics), meeting the material needs of high-end manufacturing.

Its core advantage lies in its excellent mixing performance. The twin-screw's strong shearing and conveying capabilities enable thorough mixing of a variety of materials (such as resins, additives, and fillers), making it ideal for pelletizing functional plastics (such as flame-retardant, reinforced, and antimicrobial modified materials) and recycled plastics. It also boasts a wide range of applications, processing a variety of raw materials including PP, PE, PVC, and engineering plastics, and is capable of handling highly filled and high-viscosity materials. Its high degree of automation, equipped with precise temperature control, variable frequency speed regulation, and automatic screen changing systems, ensures stable control of pellet quality and yield.

Plastic Modification Processing: This core equipment is used in the production of modified plastics. By adding reinforcing materials such as glass fiber and carbon fiber, or functional additives such as flame retardants and antioxidants, it produces high-performance modified plastics with enhanced, flame-retardant, and weather-resistant properties. These are suitable for applications requiring high material properties, such as automotive parts and electronic housings.

Masterbatch and Functional Masterbatch Production: This equipment can thoroughly mix and disperse pigments and dyes with carrier resins to create high-concentration masterbatches. It can also produce functional masterbatches with antistatic, antibacterial, and toughening properties for plastic coloring and functionalization.

Waste Plastic Recycling and Granulation: This equipment removes impurities and uniformly plasticizes mixed and impure waste plastics (such as PP/PE mixed waste and engineering plastic scraps) through the shearing and mixing action of a twin-screw extruder, achieving high-quality utilization of the recycled material. This is suitable for recycled plastic applications such as packaging and building materials.

Degradable Plastic Processing: This equipment can mix and granulate degradable resins such as PBAT and PLA with fillers (such as starch) to produce fully degradable plastic granules for use in eco-friendly products such as degradable films and tableware. Highly Filled Composite Material Production: This facility can process materials with high filler ratios (such as wood powder-filled PP and calcium carbonate-filled PE) to produce wood-plastic composites and filled and modified plastics, meeting the demand for low-cost, high-performance materials in the furniture and building materials sectors.

Engineering and Specialty Plastics Processing: This facility is suitable for blending and alloying engineering plastics such as PA, PC, and POM, as well as granulating specialty plastics (such as high-temperature and corrosion-resistant plastics), meeting the material needs of high-end manufacturing.