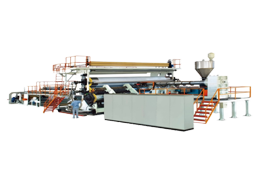

Jwell has 40+ professional companies and nine large-scale gold processing plants and three heat treatment nitriding plants, with an annual output of 3000 + (sets) sets of high-grade plastic extrusion production lines and other complete sets of equipment, marketing in more than 120 countries and regions.

Jwell Machinery's product advantages focus on four aspects: technology, experience, quality and service.

In terms of technology, the advanced processing base is equipped with exquisite craftsmanship to ensure the performance of the equipment.

In terms of experience, over 20 years of deep cultivation, rapid response to various needs and innovative development of new materials and equipment.

In terms of quality, strict quality control system combined with international certification ensures stable quality.

In terms of service, the global after-sales network and efficient response, remote monitoring help the equipment run worry-free.

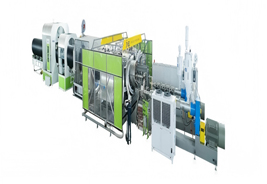

exquisite workmanship and excellent performance. Jwell Machinery is equipped with advanced parts CNC machining base and standardized assembly workshop to lay a solid foundation for product quality.

More than 20 years of deep industry experience and profound technical background. Since its establishment in 1997, Jwell Machinery has been deeply involved in the plastic extrusion industry for more than 20 years. During this period, it has accumulated a lot of project experience and has a deep understanding of plastic extrusion technology. Facing different material characteristics and customer needs, it can quickly provide mature solutions.

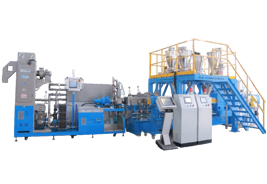

Strict system and full-process control. Jwell Machinery insists on the comprehensive implementation of "zero defect" quality management, and implements efficient quality control in all aspects from procurement and supply, production process, quality inspection to product sales. The company also took the lead in passing CE certification and ISO9001:2000 quality management system certification, and standardized its own production operations with international standards to ensure that every piece of equipment shipped meets high quality standards.

Fast response and all-round guarantee. Jwell has built a complete after-sales service network with more than 500 professional engineers. It has offices in Vietnam, Turkey, Thailand, Brazil, Bangladesh, Europe and other places, and can quickly respond to global customer needs.

We always adhere to the service concept of "customer first" and have built an after-sales service and technical support system for extruders covering the entire life cycle to protect your production operations:

Quick response and efficient service: 7×24 hours after-sales hotline is on standby at any time. After receiving the repair report, it will respond within 1 hour, and the technical team will remotely diagnose within 24 hours to ensure that equipment failures are quickly resolved and reduce downtime losses.

Professional team, worry-free technology: The technical support team composed of senior engineers has rich experience in extruder commissioning, maintenance and troubleshooting. From equipment installation and commissioning, operation training, to daily inspections and regular maintenance, it provides full-process technical guidance; for complex process requirements, it can provide customized parameter optimization solutions to improve production efficiency and product quality.

Continuous upgrades and value-added services: Regularly visit customers, collect feedback on equipment use, and provide system software upgrades, operation optimization suggestions and other services; through online training courses and technical information sharing platforms, help customers master the latest technical trends and help enterprises with technological innovation and capacity improvement.