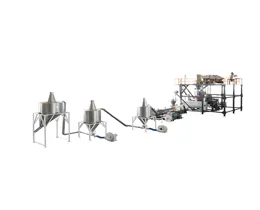

Plastic modification and filling equipment is a special equipment that combines fillers such as calcium carbonate and glass fiber with plastic raw materials through mixing, melting, extrusion and other processes to produce modified plastic particles for reinforcement, weight reduction or cost reduction.

The characteristics and advantages of plastic modification and filling equipment are that it has efficient mixing and strong plasticizing capabilities, can achieve uniform dispersion of fillers such as calcium carbonate and glass fiber with plastic raw materials, is suitable for high-proportion filling and various material modification needs, and has high production efficiency and low energy consumption. It can also ensure the stability of finished product performance and reduce pollution through automated control.