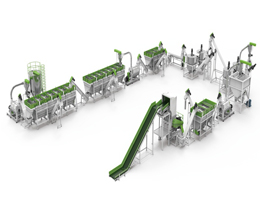

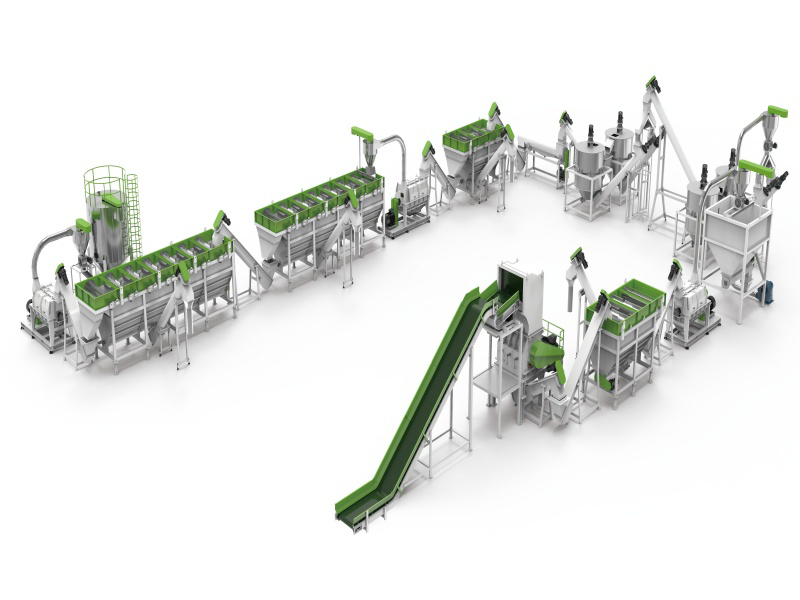

We have complete and advanced processing and manufacturing equipment for various types of plastic recycling machines. Our product structure is becoming more and more complete, and we can provide customers with a full set of solutions for plastic recycling equipment.

In the field of plastic recycling, our processing flow is as follows: First, the recycled waste plastics are shredded and crushed for pre-processing.

Then the crushed materials are sent to the plastic washing line through a conveyor belt for all-round cleaning.

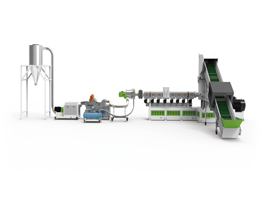

After the materials are cleaned, they enter the granulation line for recycling and granulation, and finally the required plastic particles are made to achieve resource recycling and reuse.

In the field of plastic recycling equipment, we provide customers with full-process solutions with our perfect technical system and equipment configuration:

1. Efficient crushing and shredding system: Relying on single-axis, double-axis and four-axis shredding and shredding equipment, we build a multi-stage crushing process to achieve fine processing of waste plastics. Whether it is packaging film, plastic pipes, or large plastic components, they can be efficiently crushed to fully meet the high-capacity recycling needs of various industries.

2. Deep cleaning and processing line: Integrate friction cleaning machines, rinsing sinks, dehydration dryers and other equipment to form a standardized cleaning process. It can effectively remove impurities such as oil, label paper, and mud on the surface of plastics, ensure the cleanliness of recycled raw materials, and lay the foundation for subsequent processing.

3. Precision granulation equipment: Through advanced granulation technology, precise control of parameters such as temperature and screw speed, we produce recycled particles with uniform particle size and stable melt index, which are perfectly adapted to diversified processing needs such as extrusion and injection molding.

We always focus on improving mechanical efficiency, optimizing intelligent control, and innovating environmental protection designs, upgrading traditional low-value-added recycling business to a high-value material recycling chain, helping customers achieve a win-win situation of economic and environmental benefits.

Packing: The recycled plastic packaging waste is crushed, cleaned and granulated to make recycled PE/PP particles, which are used to produce new express bags, shopping bags, food packaging films, etc., realizing the closed loop of "packaging materials → recycling → remanufacturing packaging".

Buliding: The application of plastic recycling in the construction industry is an important path to promote "green building materials" and the circular economy. By converting waste plastics into building materials, it can not only reduce plastic waste pollution, but also provide sustainable raw materials for the construction industry.