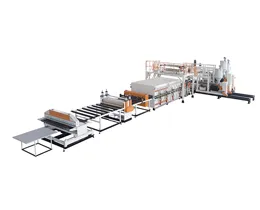

Plastic sheet extruder is a plastic processing equipment that melts plastic raw materials by heating, pressurizing and extruding to form continuous sheet materials. It is widely used in packaging, building materials, medical treatment, daily necessities and other fields. It can produce plastic sheets of various materials such as PP, PE, PVC, PS, PET, etc.

The plastic sheet and board production line has significant advantages: a high degree of automation and stable continuous production efficiency; strong adaptability to raw materials, compatible with a variety of plastic materials and modified formulas; controllable product precision, and precise adjustment of parameters such as thickness and flatness; low energy consumption, combined with energy-saving design to reduce production costs, suitable for large-scale mass production of various packaging, building materials and other sheet and board products.

Packaging: Blister packaging for food and pharmaceuticals, and pallets, leveraging their sealing and corrosion resistance to protect products.

Building Materials: PVC panels for interior decoration and advertising displays, combining waterproofing, ease of processing, and aesthetics.

Industrial Auxiliary Materials: Insulating gaskets for electronic components and protective shields for equipment, leveraging their excellent mechanical properties and insulation.

Daily Necessities: Stationery pads, storage boxes, and other products, offering lightweight, durability, and cost-effectiveness.