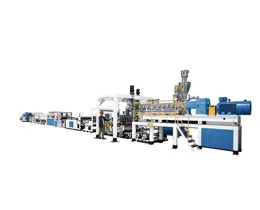

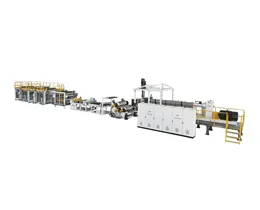

In the packaging field, plastic sheet production lines are mainly used to produce sheets of materials such as PP, PET, and PVC, providing basic materials with strong adaptability and controllable specifications for blister packaging, folding box packaging, and tray packaging of food, electronics, daily chemical products, etc.

When used in the packaging field, plastic sheet production lines can produce sheets of different materials (such as PP, PET, PVC), thicknesses and specifications on demand. They are suitable for various packaging molding processes such as blister packaging and folding boxes. They have high production efficiency and controllable costs. At the same time, they can achieve packaging functional requirements such as moisture-proof, oil-resistant, and biodegradable through material modification.