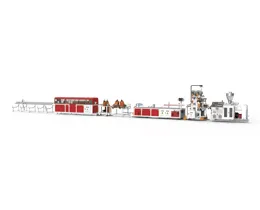

The PP profile extrusion line uses polypropylene (PP) resin as raw material. Through plasticization using a high-efficiency screw extruder, forming through specialized molds, and equipped with cooling, pulling, and cutting devices, it can continuously and stably produce a variety of PP products, including pipes, sheets, plates, and profiles. This specialized production equipment combination boasts a high degree of automation, excellent production efficiency, stable product quality, and the ability to flexibly adapt to varying specifications.

The PP profile extrusion line uses PP resin as raw material. Through precise batching, efficient extrusion plasticization, special mold forming, multi-stage cooling and shaping, and fixed-length cutting, it can stably produce PP profiles such as door and window frames and decorative strips. It has the characteristics and advantages of strong raw material adaptability, high profile dimensional accuracy, wear and aging resistance, automation and convenient changeover, and outstanding production efficiency.