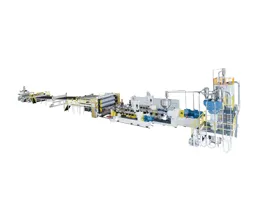

The PP sheet production line is an automated production equipment that melts and plasticizes PP plastic pellets through an extruder, extrudes them through a quick-change filter screen and extrusion die, and then cools and shapes them, trims them, and pulls and conveys them through equipment such as a three-roll calender, thereby producing PP sheets with specific thickness, width and surface quality.

PP sheet equipment has the characteristics and advantages of strong raw material adaptability (compatible with pure PP, modified PP and recycled PP), high molding efficiency, precise control of sheet thickness and flatness, low energy consumption in the production process, and stable output of PP sheets of different specifications (thickness 0.1-5mm), suitable for packaging, blister packaging and other fields.