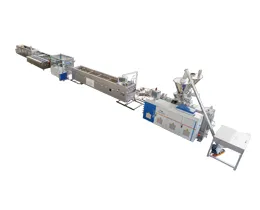

The solid wall pipe extrusion line is a dedicated equipment that efficiently produces solid wall pipes made of PVC, PE, PP, etc. through a series of processes such as heating and melting raw materials in an extruder, shaping in a mold, and cooling and pulling. It can be adapted to the manufacture of pipes for different purposes such as water pipes, drainage pipes, and threading pipes, ensuring uniform wall thickness, dense structure, and precise dimensions.

The solid-wall pipe extrusion line has the advantages of a high degree of automation, stable production efficiency, and accurate pipe forming accuracy (uniform wall thickness and dimensional compliance). It can also be adapted to the production of various raw materials such as PVC and PE, as well as pipes for different purposes such as water supply pipes and conduit pipes. At the same time, it has low energy consumption and is easy to operate, which can meet the needs of large-scale and customized production.

Using raw materials such as PVC, PE, and PP, the extruder melts and plasticizes the material through a screw, then continuously extrudes it through a specific die. This allows for precise control of parameters such as pipe diameter and wall thickness. This continuous production model, with a high degree of automation, consistently produces solid-wall pipes with smooth exteriors and uniform wall thickness, making it suitable for solid-wall pipe applications in water supply and drainage, municipal engineering, and agricultural irrigation.