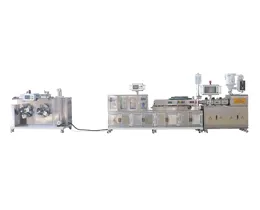

The small plastic tube extruder is specialized equipment for producing small-diameter plastic tubing (typically ranging from a few millimeters to tens of millimeters). Using raw materials such as PE, PVC, and PP, the extruder melts and plasticizes through a precision screw, then continuously extrudes the tubing through a small mold and a cooling and shaping system. Its compact structure and strict dimensional accuracy ensure stable production of small tubes with uniform wall thickness and smooth interiors. Suitable for applications such as medical infusion tubing, precision instrument catheters, and household water dispenser tubing.

The small diameter pipe extrusion line has high product precision (diameter tolerance is usually controlled within ±0.03mm), a high degree of automation and stable molding, and can efficiently produce small diameter pipe fittings.