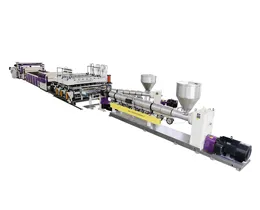

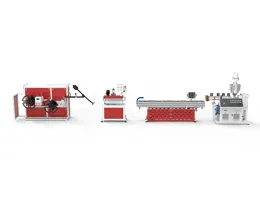

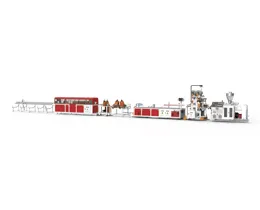

Jwell product structure of profile extrusion machine for the construction industry is comprehensive, covering machines for producing various profiles like windows, doors, and decking. We are dedicated to providing customers with a full set of solutions, from raw material processing to final product extrusion, ensuring high-quality, efficient, and reliable profile production for global construction projects.

PVC profile equipment has the advantages of stable extrusion molding, high degree of automation, adaptability to the production of profiles of different specifications, low energy consumption in the processing process, and high qualified rate of finished products. It can efficiently meet the needs of mass production of PVC profiles in fields such as building doors and windows.